|

| Our Thanksgiving Ham |

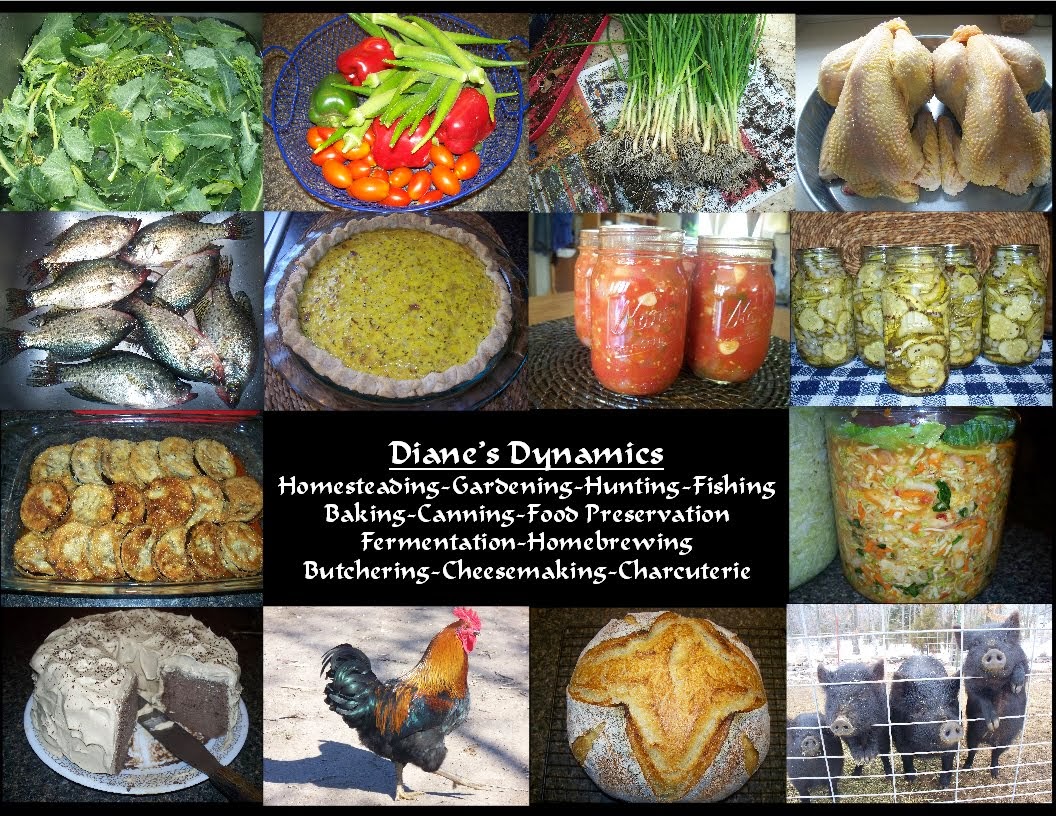

This is my favorite time of year for raising pork because we

raise American Guinea Hogs for a subsistence, homesteading lifestyle rather

than for profit – meaning we do not have a lot of expensive equipment or a cold

room, therefore like with most homesteading enterprises, there are seasons for

everything we do for specific reasons. For instance, my previous blog post

focused on butchering shoats (young culls) during the summer months so that we

do not have to feed out or castrate less-than-stellar stock. I get rid of ALL

my unwanted boars by the age of 3-4 months. Occasionally I will register and/or

sell one, but I have learned the hard way that only the very best stock should

be registered (or sold unregistered) for breeding, and that it comes back to

bite me (and other breeders) in the butt when we sell poorly-bred stock for any

reason, even as a stop-loss economic scenario. Eat them, feed them to your

dogs, share the meat with your neighbors, but do NOT sell an animal capable of

breeding that you would not breed yourself. Oftentimes people with the best of

intentions but little homesteading/butchering experience want to buy feeders to

eat, but then they find themselves in over their heads with pregnant gilts or

too many uncastrated boars which they then have to unload themselves for their

own stop-loss economic situation. This is one of the reasons people expect

heritage pork to be cheap – because around here, you can buy someone else’s $500

mistake at an auction for $25. I’ve even seen full-grown (300#+ AGHs!) for free

on Facebook groups and Craigslist. Guess how I learned the hard way about

this?!

Now, let us talk a minute about “Charcuterie.” It is the

current fad amongst dedicated foodies who want the very best heritage meats and

those who work in the food industry, but it is nothing more (and yet everything

great!) about preserving meat safely, long-term, without refrigeration. It also

includes some things that do need cool or cold storage, like fresh sausage, terrines, pates. And if you

are not a chef, this word can be a little scary because it can become quite

complicated – though like everything else worth doing (bread-building,

cheesemaking, etc.), you start with a simple foundation and continue building

on that. Fresh bulk sausage is one of the easiest and at the end of this post,

I will share my simplest, most versatile spice mix for breakfast sausage to be

made in 5# batches. But this post is for the holidays, so let us talk about… HAM.

This is the American-style ham most of us are familiar with that has been

lightly smoked and fully-cooked, but needs to be glazed and fully-reheated for

serving. You will find that your own looks and tastes nothing like those nasty,

wet, particle-board-textured abominations that are passed off as “hams” at the

grocery.

Because I have already butchered my shoats in the 50-75#

range over the summer, next up for the fall and winter are those few larger

gilts, barrows and cull sows I saved for fast growth, large size and age. I

have started butchering them by size for the fall, starting with the smallest,

so that by the time truly cold weather sets in, I can turn the very best of the

best into slow-cured hams (like Proscuitto/Country Ham), which are often cured

for at least a year, sometimes longer. But for this post, and just in time for

Christmas and New Years, let us start out by butchering a cull hog (young gilt

or barrow) in the 120-150# range and we will end up with a couple of

incredible-flavored, boneless, 7# fresh hams to be cured and smoked for the

holidays. You will need about 2-3 weeks from start to finish for a hog this size,

so get started now.

Sorry to keep repeating this, but for me, SCALD AND SCRAPE

is the ONLY option when dealing with a hog you have taken this much

time, love and pride in raising. I personally believe that skinning is a last

resort and something to be done only when you are far afield from civilization,

or maybe you are just planning on grinding the entire carcass because you have

too many pigs or you had to unexpectedly turn a breeder into pork due to injury

or accidental death. Professionally, hogs have ALWAYS been scalded and scraped, then hung and rested for a couple of days before proceeding with butchery. You end up with a carcass that is free of stray hairs, where the

fat cap is smooth and beautiful and if you still remove the skin and some fat for

cracklings/lard from primals/subprimals, you can do it at a much more leisurely

pace and with at least a little artistic finesse rather than it looking a

beaver helped you peel hard-boiled eggs! Seriously. Watch some youtube videos

with the old-timers in Kentucky/Virginia or the Amish who still have family/community

hog butchering parties – sometimes the hogs are too large to dip in 160-degree

water, so they cover them with burlap or old towels before dribbling scalding

water on them and scraping. This post is specifically about smaller breeds of

hogs though, so there’s rarely any excuse. Even torching them with a

flamethrower is preferable to skinning (for me), though it is tricky because

you don’t always get the hair follicle out of the skin. Blowtorch the hooves

until the cuticle pops off and brine/smoke those trotters, hocks and shanks as well

so you have seasonings for your winter bean soups. Or for pickled pigs feet.

If you have a cold room, you can leave the whole hog hanging

for a couple days to allow rigor to relax before butchering. I do not have a

place cold enough except maybe during a severe winter storm, so I split mine

then pack them in a marine chest full of ice. (They will actually keep safely

for longer than a few days as long as you keep the old water drained off and

keep them packed in fresh ice, though likely someone will dispute me on this.) Of

late, I’ve been splitting the whole hogs before removing the head so that it’s

easier to harvest the tongue, remove the brain, etc., but you may want to save

the skull. Whichever. So you will end up with something like this:

|

| 120# Gilt |

I always remove the kidney, leaf lard, tenderloin, and whole loin before doing any other processing. To remove the back leg, simply cut along the seam where the belly meets the leg. (Try to keep the belly cut square with this breed, or you won't have any belly left!) If you have not already removed the rump/sirloin, saw thru the vertebrate to finish this cut. Remove the trotter (foot) from the hock/shank end by finding the bend in the joint. (It is not important that this cut be perfect – you are going to remove all the bones and trim the overhang anyway. AGHs of this size have very little in the way of hocks/shanks to begin with) This is what you should end up with. (I know, not very appetizing, but just wait!)

Here is a basic diagram of all the piggy parts should you

need to know, but don’t get all bothered about perfection. That takes practice

and all your mistakes end up in the sausage bin or stock pot.

Now, if you ended up with a beautiful scald and scrape job

(no hair follicles), you can either leave the skin on, or choose to carefully

remove it. I had to remove the skin on this one. Leave as much of the fat as

you can but you may have to trim if the hog is obese. There will be a point

right in the center where you will cut thru into the meat if you don’t do this

carefully, which I did on one of the hams. It would have looked horrible had I

skinned to begin with. By feeling and looking for the seams between muscles,

remove the aitch bone with a small sharp knife, then continue until you’ve removed

the larger leg bone. I removed the

shank, but left the bone in and brined/smoked them with the hams to season soups

with.

And finally, trim off any overhang and square off the

boneless slab:

They will look like this when rolled. (See where I nicked

thru the fat when skinning on that one.)

Weigh each cut and know that you will need to inject and

brine them for at least half a day per pound. It is okay to brine a little

longer if that suits your time frame. They will also need a day to dry on a rack

in the fridge before smoking. These

weighed about 6.5# each and I let them go almost 2 weeks, so it’s a forgiving

process. It is however, VERY important to inject the brine thoroughly all thru

the muscles or you will end up with a combination of pink ham and gray pork

roast where the brine didn’t penetrate.

Let’s talk just a moment about curing salt. There is way too

much MISINFORMATION out there about nitrites and nitrates. I’ve heard lots of

people say they cannot eat nitrites and yet have no idea what the chemical

process is that converts harmless nitrites into nitrates (of which there is no

real evidence are harmful in small quantities either). For the record, almost

all of the cured products you buy from an average grocery store

(bacon/hams/most deli meats) use NITRITE. Bacon may not be sold in the US

containing NITRATES. Nitrates form thru long fermentation (like with salami,

summer sausage and other specialty meats) from nitrites. Sometimes they are

added to these longer-cured products for safety, but simple charcuterie rarely

uses them. If you want to skip it for this brine, you can, but you will not be

making ham, you’ll just be making a pork roast. It will not have the beautiful

pink color of a ham, nor will it taste the same. Please skip the Tender-Quick

and Sugar Cure available from Morton’s and just order yourself a canister of #1

Curing Salt (Sodium Nitrite, sometimes just called pink salt, but not to be

confused with pink Himalayan sea salt). It takes only a tiny amount and a pound

will last you awhile and you’ll have the versatility of using it for all of

your basic curing. Also, PLEASE weigh out your ingredients, especially for

curing and baking. You will be shocked to see the difference between weight and

volume.

From here on out, I’ll be adapting the recipe (available

from their websites) from Ruhlman/Polcyn’s book “Charcuterie” for:

The Brine (enough for 15# meat)

*1 gallon/4 liters water

*1 ½ cups/350 grams kosher or sea salt

*2 packed cups/360 grams light or dark brown sugar

*1 ½ oz/42 grams/8 teaspoons #1 Curing Salt

*1 gallon/4 liters water

*1 ½ cups/350 grams kosher or sea salt

*2 packed cups/360 grams light or dark brown sugar

*1 ½ oz/42 grams/8 teaspoons #1 Curing Salt

Here’s the fast and easy way to do this: Get a gallon

pitcher and add the dry ingredients. Heat about 2 cups of water in the

microwave to boiling and pour over them. Whisk until dissolved, then add ice and

continue stirring until the solution is cool. Fill the pitcher to the gallon

mark with cold water.

|

| (Shank/Hock portion lying on top of the ham slabs) |

Using a bulb baster or syringe, inject the meat thoroughly

with this solution, then submerge the meat completely in the solution. You can

weight it down or just turn it twice a day. The day before smoking, rinse, dry and tie the

meat and let it dry on a rack in the fridge or cool place. Here is a nifty little tutorial that shows

you how to tie meat: http://www.junedarville.com/how-to-tie-meat.html

If you have trouble getting it started,

use a few plastic strap ties to hold the meat in place while you tie (remember

they can be joined together to make them long enough). Cut them loose after

tying. And here they are, ready to go on the smoker:

Now here’s where I deviate from the recipe a little. The

recipe suggests that they be hot smoked (200 degrees) for 2 hours, then glazed

and smoked to an internal temp of 155 degrees. As we have primarily only oak

and hickory to use for smoking, that leaves a really strong smoke flavor that

may be a little more than most people are used to. It also blackens the glaze,

which I don’t find terribly attractive. So with this size hams, I smoked them

at 200 degrees for about 4 hours, then glazed them and transferred them to the

oven (uncovered) and brought them to the internal temp of 155. Let the hams

cool completely. At this point, if you want to vacuum seal them or freeze them

or just wrap them and keep them cool for a couple of days, you’re done with the

hard part. If you want to serve the ham whole and hot, reheat it in a 275

degree oven until it’s warm in the center (no safety concerns here, it’s fully

cooked). I prefer to run the whole ham thru the deli slicer and serve it with

the glaze as a sauce on the side. This ham has so much flavor, a big, thick

slice is really overkill – thin slices will likely be more appreciated by

grandpa’s dentures and young children than thick steaks. And you’ve got all

that deli meat ready for sandwiches if there’s any left!

Glaze/Sauce Recipe:

*3 cups brown sugar

*1 (12oz) jar brown mustard (or whatever mustard you like)

*A jar of your favorite jam or chutney – I used wild plum (also a good way to use up whatever jams/jellies are leftover in the fridge)

*3 cups brown sugar

*1 (12oz) jar brown mustard (or whatever mustard you like)

*A jar of your favorite jam or chutney – I used wild plum (also a good way to use up whatever jams/jellies are leftover in the fridge)

By the way, here was my first attempt at hams last year.

These were bone-in, skin on and there was a good layer of fat cap. They were

still rolled and tied and used the same method. Remove the skin and some of the fat before the

final glaze and reheat.

And as promised, my favorite recipe for a simple but

flavorful spice mix for breakfast sausage – mild enough no one has complained

about it, flavorful enough to pack a punch. I have found this to be excellent

on both pork and red meats. Mix up a jar of it in the spice grinder and it

would make a nice holiday or house-warming gift for someone who orders those

expensive packets of seasoning mix for their venison sausage. I have weighed

one batch of this and found it to weigh about 45 grams, which comes out to a

scant 2 teaspoons (9 grams) per pound of meat.

For 5# of sausage:

1 teaspoon black or white peppercorns, whole

1 tablespoon whole coriander seeds

2-3 dried bay leaves

1 tablespoon rubbed sage

1 teaspoon each dried whole thyme, marjoram, pepper flakes

½ teaspoon garlic powder

2 teaspoons salt

1 tablespoon whole coriander seeds

2-3 dried bay leaves

1 tablespoon rubbed sage

1 teaspoon each dried whole thyme, marjoram, pepper flakes

½ teaspoon garlic powder

2 teaspoons salt

Now. Go make some bacon!!!